|

|

Investigation

of Hybrid Processes of Metal Treatment and Development of Integrated Plasma Torches

for Laser+Plasma Arc Welding, Cutting and Surfacing

|

Sample

R&D Project

Open for collaboration!

|

The main purposes

of this project are: combining of the advantages of the known

methods of laser and plasma transferred arc treatment of metals and

widening of their possibilities within new hybrid processes of laser

+ plasma arc welding (LPAW), cutting (LPAC) and surfacing (LPAS).

The project provides:

theoretical investigations of the physical phenomena occurring at hybrid

processes of metal treatment, development of integrated laser-arc plasma

torches for LPAW, LPAC and LPAS, as well as their technological examinations.

The expected results

are: improving of efficiency and productivity of the laser

methods of metal treatment, as well as widening of metal thickness range

for the laser welding, cutting and surfacing without considerable degrading

of their quality and increasing of the laser power used.

Objectives:

- To investigate interaction of the focused

laser beam with the plasma transferred arc and their combined effect

on different metals as applied to LPAW, LPAC and LPAS of various materials,

including aluminium alloys.

- To develop the main principles of the

hybrid processes and concept of the integrated laser-arc plasma torches

for LPAW, LPAC and LPAS.

- To create the prototypes of integrated

plasma torches for laser + plasma welding and surfacing as applied

to the special technological processes.

- To carry out the experimental and technological

examinations of LPAW, LPAC and LPAS.

Brief

background:

Alongside with the conventional methods

of metal joining and treatment that use arc (plasma transferred arc),

laser or electron beam heating of metal, the hybrid technological processes

are increasingly developing. The essence of these processes is in the

simultaneous using of two different heat sources, for example, the laser

beam and the electric arc (see, e.g., V.S. Gvozdetsky, I.V. Krivtsun

et al., Laser-arc discharge: Theory and applications, Welding and Surfacing

Rev., Vol. 3, Harwood Academic Publishers, 1995).

In the realisation of the hybrid laser-arc processes for welding and

cutting the application of additional arc plasma heating of metal increases

the efficiency of the corresponding laser process. This is especially

important when low-power lasers are used. On the other hand, the usage

of the electric arc together with the laser beam improves the spatial

stabilisation of the arc root on the metal surface at low current and

high travel speed. It allows to increase greatly the stability and productivity

of the corresponding arc process.

The most rational scheme of the hybrid welding and surfacing processes

is the scheme, using plasma transferred arc with the introducing of

the laser beam along the axis of plasma-shaping channel of the plasma

torch. In contrast to the known methods of laser-arc welding and cutting,

this scheme ensures the required coaxial nature of the effect of the

laser beam and the electric arc on a workpiece. Moreover, this scheme

is characterised by new possibilities of mutual control of the characteristics

of the plasma arc and the laser beam, as sources of thermal and dynamic

effects on the surface of metal being treated.

The coaxial combination of the laser beam with the plasma arc requires

special devices to be developed - the integrated laser-arc plasma torches

(see, e.g., I.S. Dykhno, I.V. Krivtsun and G.N. Ignatchenko, Combined

laser and plasma arc welding torch.

Pat. No.5700989, USA, Int. Cl. B23K 26/00, 10/00, published 23.12.97),

the special feature of which is the electrode unit design, that enables

the laser beam to be introduced along the plasma-shaping channel. The

design peculiarities of such devices are determined by the parameters

of the laser beam used (CO2 or Nd-YAG laser, power range,

mode and focusing of the initial beam); the kind and flow rate of plasma

gas (Ar, He, or their mixtures, air, O2, or N2);

the current range and polarity of the plasma arc, as well as the kind

and thickness of the metal being treated.

Our team has great experience in the field of gas discharge physics

(arc, optical and combined laser-arc discharge), engineering of plasma

and integrated equipment for metal treatment, as well as its industrial

applications. To our mind, the hybrid laser + plasma technologies (LPAW,

LPAC, LPAS) present a new step in the development of material treatment

methods and their industrial applications are very important at this

time.

Program of the theoretical

investigations:

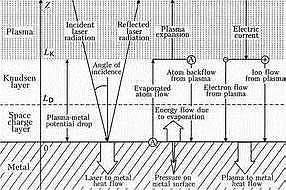

Stage

I. Development of 1D model (one-dimensional, local model) of the

physical processes occurring in a system "laser radiation - near-surface

plasma - metal surface", as applied to laser and hybrid methods of metal

treatment: Stage

I. Development of 1D model (one-dimensional, local model) of the

physical processes occurring in a system "laser radiation - near-surface

plasma - metal surface", as applied to laser and hybrid methods of metal

treatment:

- Investigation of metal evaporation

into near-surface plasma (shielding or plasma gas at the atmospheric

pressure). Calculation of particle (mass) and energy flows from the

metal, pressure at its surface and temperature of heavy particles

in the plasma (with taking into account the reversed particle flow)

as functions of local values of the metal surface temperature and

Mach number outside Knudsen layer.

- Determination of the near-surface plasma

composition (ionisation-recombination processes with taking into account

one-dimensional mutual diffusion of shielding gas and metal vapor

particles), depending on the metal surface and plasma electron temperatures.

Calculation of thermodynamic characteristics (mass density, specific

heat), transport coefficients (viscosity, thermal and electrical conductivity)

and optical properties (plasma radiation losses, refractive index

and absorptivity of laser radiation) for this multi-component plasma.

- Investigation of laser radiation (CO2,

Nd-YAG - lasers) absorption and reflection by the metal surface (with

taking into account refraction and absorption of the laser radiation

in near-surface plasma). Calculation of laser heat flow into the metal

as a function of local values of the metal surface and plasma electron

temperatures, intensity, polarisation and angle of incidence of the

laser radiation.

- Investigation of energy balance of

the near-surface plasma (laser or combined plasma). Calculation of

plasma electron temperature (with taking into account one-dimensional

plasma expansion).

- Calculation of electric potential distribution

in the near-surface region and flows of particles and energy from

plasma to the metal surface as functions of local values of electric

current density in plasma and metal surface temperature.

- Determination of total energy balance

and pressure on the metal surface as functions of local values of

arc current density, incident laser radiation characteristics and

metal surface temperature.

Deliverables:

Local dependencies of the heat flow into

the metal and pressure at its surface on this surface temperature, laser

radiation characteristics, electric current density in the near-surface

plasma and its expansion velocity, as applied to laser and hybrid processes

of metal treatment.

Stage II.

Development of 2D computer models (two-dimensional, axisymmetrical models)

of the processes inside the near-surface plasma, on the surface and inside

the metal at laser and hybrid methods of metal treatment with the motionless

heat source:

- Development of computer model of the

near-surface laser plasma with axisymmetrical distributions of the

plasma and laser beam parameters (with taking into account laser plasma

expansion).

- Investigation of non-stationary thermal

processes inside the metal with preassigned boundary conditions on

its surface (with taking into account movement of the phase transition

boundaries).

- Investigation of the metal surface

and liquid metal dynamics with preassigned boundary conditions for

erosion and pressure on its surface (for given melting boundary geometry).

- Development of 2D computer model of

the cathode phenomena at hybrid processes (with taking into account

electron emission peculiarities, cathode spot mode and near-cathode

plasma expansion).

- Development of 2D computer model of

the anode phenomena at hybrid processes of metal treatment (with taking

into account arc current distribution inside the anode region and

near-anode plasma expansion).

- Complex simulation of non-stationary

thermal and dynamical processes inside the metal with self-consistent

boundary conditions on its surface at laser and hybrid methods of

metal treatment (for different arc polarity and motionless heat source).

Deliverables:

Self-consisted 2D computer models of non-stationary

metal penetration processes at laser and hybrid methods of metal treatment

with the motionless heat source. This models can be used for computer

estimation of the metal penetration dynamics, depending on the metal

thickness, initial laser beam characteristics (wave length, power, mode

and focusing conditions), arc current and its polarity, as well as the

time interval of their affecting on the metal.

Stage III.

Development of 2+3D computer models (two-dimensional, axisymmetrical near-surface

plasma model and three-dimensional model of thermal and dynamical processes

inside the workpiece) of metal penetration at laser and hybrid welding:

- Investigation of quasi-stationary thermal

processes inside the metal with preassigned boundary conditions on

its surface (with taking into account movement of axisymmetrical heat

source).

- Investigation of quasi-stationary dynamics

of the weld pool surface and liquid metal dynamics with preassigned

boundary conditions (axisymmetrical) for erosion and pressure on its

surface (for given melting boundary geometry).

- Determination of self-consisted boundary

conditions (axisymmetrical) on the weld pool surface as applied to

laser and hybrid processes.

- Complex computer simulation of metal

penetration at laser and hybrid welding of different metals.

Deliverables:

Self-consisted 2D, 3D computer models of

quasi-stationary metal penetration processes at laser and hybrid welding.

These models can be supplied by Windows friendly interface for future

commercial realisation of the developed software. This software can

be used for computer simulation of laser and hybrid welding of metals,

depending on the metal thickness, initial laser beam characteristics

(wave length, power, mode and focusing conditions), arc current and

its polarity, as well as the welding speed.

|